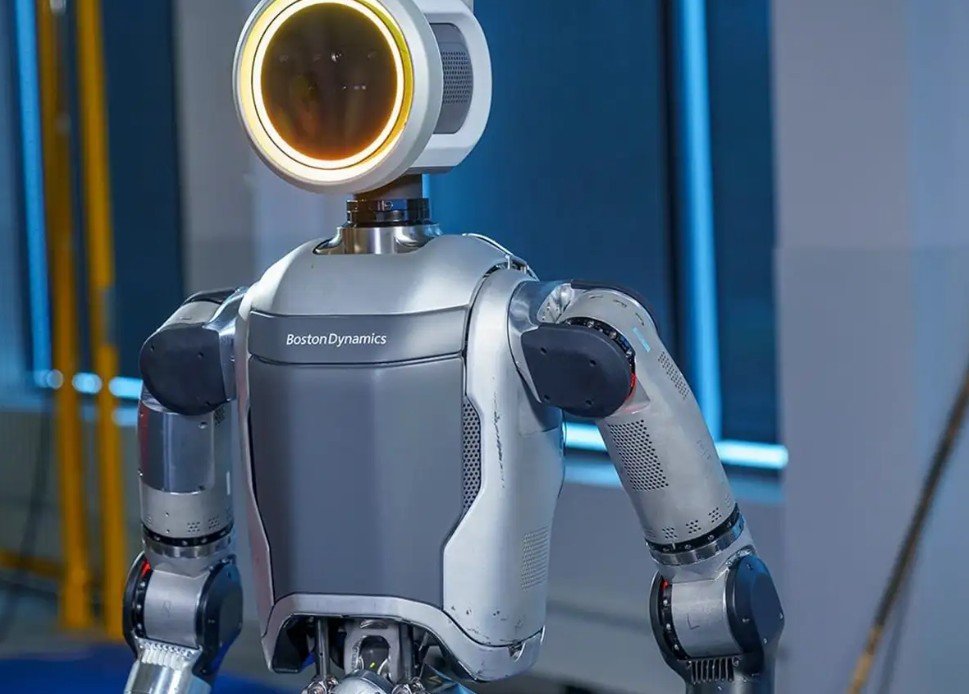

Boston Dynamics has taken its most famous humanoid robot out of the lab and into a live industrial setting. Atlas, now fully electric, has begun early factory trials at Hyundai Motor Group’s new manufacturing site in Georgia, offering a rare glimpse of how humanoids might actually fit into real-world production.

The test marks a symbolic shift. This time, the robot wasn’t flipping or parkouring for a demo reel. It was working.

A First Real Test Beyond the Lab Walls

For the first time, Boston Dynamics allowed Atlas to operate inside an active automotive facility rather than a controlled research space. The trial took place at Hyundai Motor Group’s new plant near Savannah, Georgia, where the company is building out its next phase of US manufacturing.

Atlas was shown handling basic factory tasks, including sorting and moving automotive components. These were early-stage jobs, nothing flashy, but that was the point. Real floors, real equipment, real constraints.

The demonstration aired on 60 Minutes, pulling back the curtain on how artificial intelligence is being applied to physical labor. Instead of being scripted line by line, Atlas learned through observation and repetition.

This was less spectacle, more stress test.

Hyundai’s Bigger Bet on Robots at Scale

Hyundai’s interest in robotics goes well beyond a single humanoid trial. The automaker, which acquired Boston Dynamics from SoftBank in 2021, has been open about its long-term ambitions to integrate robots deeply across manufacturing, logistics, and mobility services.

At the Georgia facility alone, nearly 1,500 workers are already operating alongside more than 1,000 traditional industrial robots.

Humanoids add a different angle. They can move through spaces built for people. They can adapt when layouts change. And they don’t require factories to be rebuilt from scratch.

During the Atlas test, Hyundai employees were seen observing the robot as it practiced component handling independently. No cages. No choreographed safety theater. Just watchful eyes and cautious optimism.

Executives described the effort as an early step, with more details expected later this year at CES in Las Vegas.

The Money, the Market, and the Pressure Cooker

Interest in humanoid robots is rising fast, and the numbers reflect that momentum.

Goldman Sachs estimates the global humanoid robot market could reach $38 billion by 2035. That projection has become a favorite slide in investor decks.

Meanwhile, Forbes reported that humanoid robot developers attracted roughly $4.6 billion in investment during 2025 alone.

Still, the path from prototype to payroll replacement is not smooth. Reliability remains uneven. Costs are high. And factory environments are unforgiving when systems fail.

Boston Dynamics executives have been careful to cool expectations. Yes, the interest is real. Yes, the capital is flowing. But large-scale deployment, they say, is still some distance away.

Atlas Gets a Full Electric Makeover

Atlas today looks nothing like its early hydraulic predecessor. The robot has been completely redesigned into a fully electric system, making it quieter, more efficient, and easier to maintain.

Its most noticeable changes include:

-

A three-fingered gripper built for precise object handling

-

Joints capable of full rotation, allowing more human-like movement

-

A slimmer profile that fits more naturally into factory layouts

The biggest shift, though, is how Atlas learns.

Instead of relying on hard-coded instructions, the robot is trained through teleoperation and simulation. Human operators guide Atlas remotely. Those movements are captured, analyzed, and then replayed across thousands of simulated robots at once.

Basically, one human teaches an army of digital Atlases, and the best behaviors rise to the top.

It’s messy. It’s iterative. And it looks a lot more like how people learn than how machines used to.

Competition Heats Up, Oversight Still Matters

Chief executive Robert Playter has been candid about the competitive landscape. Well-funded startups, particularly in China, are moving quickly and pouring resources into humanoid development.

Boston Dynamics still believes it holds an edge on technical capability, especially in mobility and balance. But Playter has also stressed a less glamorous truth.

Humanoids won’t replace people outright.

Even as robots take on repetitive or hazardous tasks, humans will remain central to training, maintenance, supervision, and deployment. Someone has to keep these systems running. Someone has to decide when they stop.